Case Study: Pulp & Paper

A major OSB (oriented strand board) manufacturer in Oakdale, Louisiana, required urgent assistance during a critical turnaround.

Large hydraulic presses needed valve maintenance, but the facility was unable to remove heavily torqued Allen head bolts securing the valves.

CHALLANGE

Eight large hydraulic valves—each secured by 20 Allen head bolts—needed to be removed. A previous contractor managed to de torque only 20 bolts over 3 days while dealing with equipment failure. The bolts were torqued to approximately 15,000 ft-lbs, with some resisting even at 20,000 ft-lbs. Cutting the bolts posed serious fire hazards due to residual hydraulic oil, and delay would have jeopardized crane scheduling and restart timelines.

SOLUTION

We proposed combining two specialized service lines:

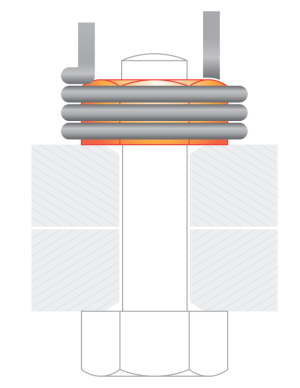

- Induction Heating: Custom-fabricated a 1.25” diameter coil to heat bolt shafts internally, utilizing portable induction heating, in order to reduce the required torque.

- Hydraulic Torquing: Used portable torque equipment to complete bolt removal safely after heating.

MOBILIZING WITHIN 24 HOURS, WE PERFORMED ALL WORK ON-SITE OVER TWO DAYS.

EXECUTION

Each bolt was heated for approximately 45 seconds, allowing torque to drop significantly (some from 20,000 to as low as 12,000 ft-lbs). The risk of fire was eliminated, and valve components were preserved.

Close coordination with the client ensured alignment with crane operations and overall turnaround scheduling.

RESULTS

- All 160 bolts removed in 2 days

- Outperformed previous contractor by more than 6 times the pace

- Zero defects or damage to valves

- No fire risk

- No equipment damage

- Enabled on-time valve reinstall with no crane delay

- Client extended scope to include bolt reassembly

CONCLUSION

By combining our speciality induction heating and technical bolting expertise, we delivered a rapid, risk-mitigated solution under extreme torque and time constraints. Our approach highlights the value of innovative thinking and multi-discipline capabilities in industrial turnarounds.

Copyright 2022 Industrial Thermal Services, LLC. All Rights Reserved.