Case Study: Finite Element Analysis for Post Weld Heat Treatment of a Pressure Vessel Nozzle Joint

Finite Element Analysis for Post Weld Heat Treatment of a Pressure Vessel Nozzle Joint

CLIENT OVERVIEW

A petrochemical company based in the U.S. was fabricating a large, high-pressure vessel with multiple nozzle attachments. These full-penetration welded nozzles are critical to the vessel’s safe operation, which involves extreme pressure and temperature. To meet ASME Section VIII requirements and ensure long-term reliability, the client needed Post Weld Heat Treatment (PWHT) to relieve residual stresses and enhance material toughness.

CHALLENGE

The client had experienced cracking in similar nozzle joints during previous projects. These failures were linked to high residual stresses from welding, improper heat treatment cycles, and thermal gradients that caused distortion. Without intervention, the risk of future cracking posed a significant threat to operational safety, reliability, and compliance.

SOLUTION

To address these concerns proactively, the client engaged our team to perform Finite Element Analysis (FEA) to simulate and optimize the PWHT process. The scope included thermal and structural simulations of the nozzle-to-shell joint, using realistic heat treatment parameters.

The project was completed off-site by our engineering team using advanced FEA tools.

EXECUTION

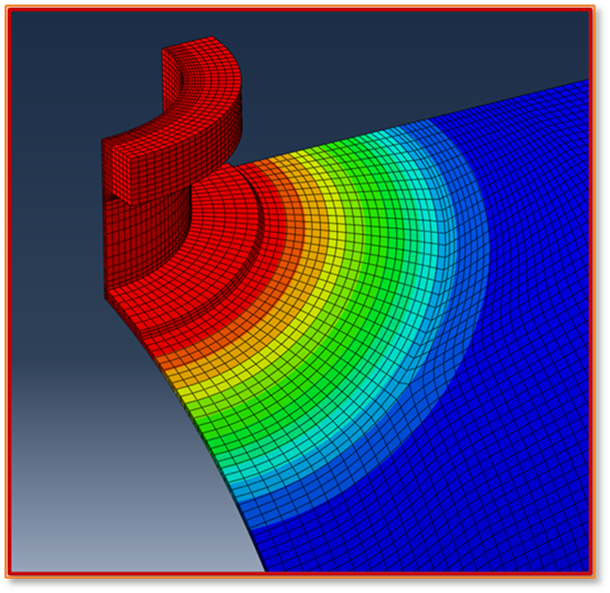

- Modeling: A 3D CAD model of the nozzle joint was developed and imported into FEA software (e.g., ANSYS, Abaqus).

- Material Properties: Realistic, temperature-dependent material properties were applied to simulate behavior during PWHT.

- Thermal Analysis: Simulated a standard PWHT cycle (600°C soak for 2 hours), including controlled heating and cooling phases.

- Structural Analysis: Coupled with thermal data to predict residual stress relief and deformation.

- Validation: Results were validated against data from thermocouples and strain gauges during a trial heat treatment.

Throughout the process, the team emphasized accuracy, safety, and code compliance. Adjustments were made to heating rates and insulation layout to reduce hot spots and ensure uniform heat distribution.

RESULTS

Residual stresses were reduced by over 70% following the PWHT, significantly improving the structural integrity of the nozzle joint. Distortion at the nozzle edge remained well within acceptable limits, ensuring dimensional accuracy. The analysis also identified thermal hot spots, which were successfully mitigated by refining the insulation layout to promote more uniform heating. As a result, the optimized process minimized rework, enhanced code compliance, and ultimately saved both time and cost for the client.

CONCLUSION

This project demonstrates how advanced FEA can proactively prevent equipment failure, optimize critical thermal processes, and ensure code compliance. By partnering early in the fabrication process, we helped the client reduce risk, improve safety, and enhance the performance of a high-value pressure vessel.

Copyright 2022 Industrial Thermal Services, LLC. All Rights Reserved.